Production Capabilities

A commitment to world-class quality

Novoflex delivers world-class quality in all of our products and solutions. From our clean rooms, to the assembly lines and QA process, we aim to exceed customer expectations. We are proud this commitment to excellence in our production capabilities has earned Novoflex the trust of global customers and partners.

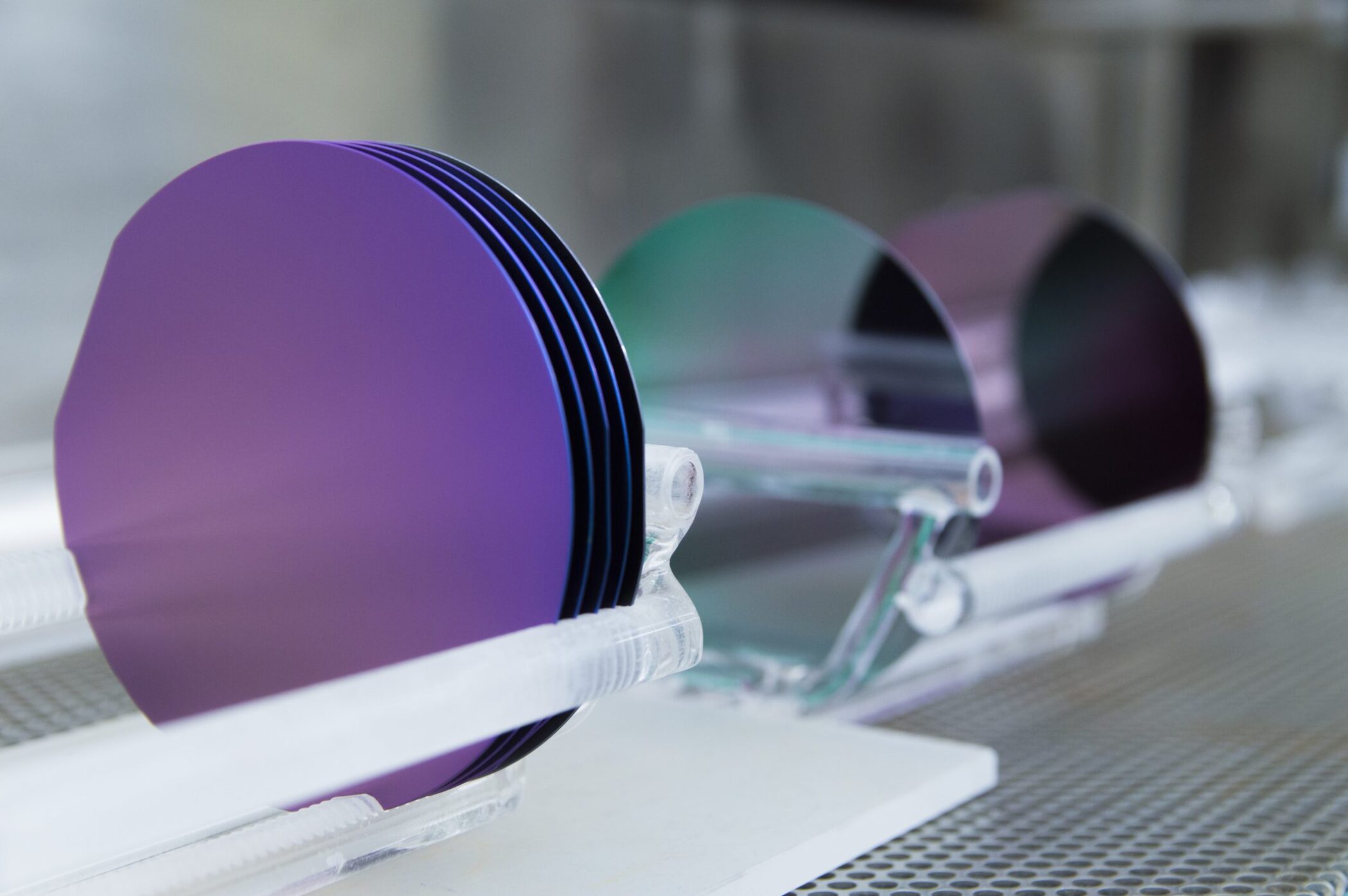

Cleanroom Environment

Leading Standards

Our facilities conform to the US FED STD209E standard (the equivalent of cleanroom class ISO 7 in ISO14644-1).

Strict Requirements

This cleanroom classification requires for every cubic feet, to have no more than 10,000 particles, with particle size of 0.5 µm.

Continuous Maintenance

We adopt a number of measures to ensure strict adherence to relevant standards (i.e., installation of top-of-the-range HEPA filter). Regular maintenance of the cleanroom includes chemical wash of the ESD flooring.

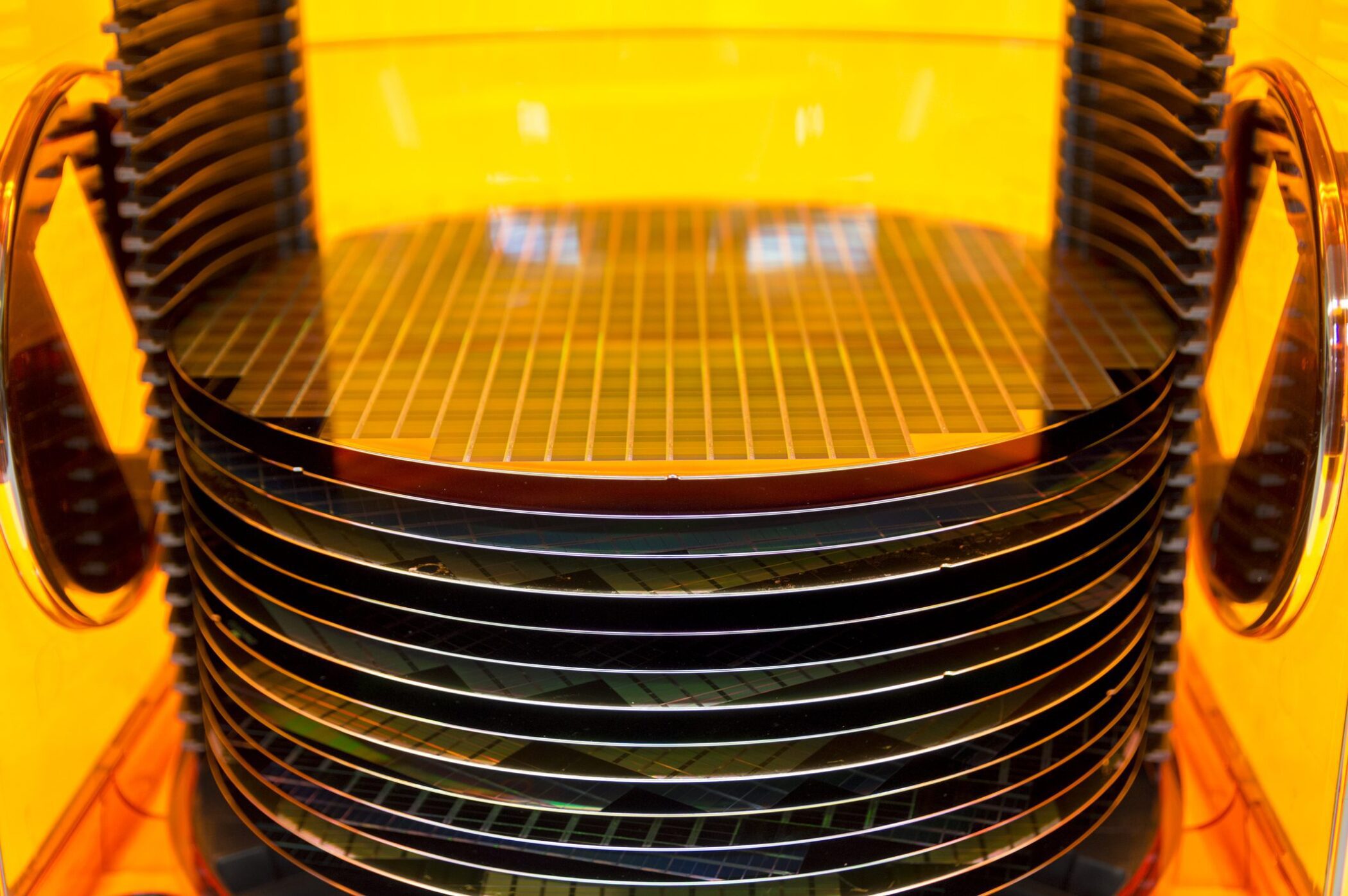

State-of-The-Art Production

Our production line machinery is from leading global semiconductor equipment manufacturers. We continually invest in the latest technologies, so we can produce cutting edge solutions.

Wafer Dicing

Our DISCO DFT 6340 wafer dicing machine can handle 6″ and 8″ wafers.

Wire Bonding

Our ESEC 3008SC/ESEC 3100/ESEC 3008SC PLUS wire bonding machines can accomplish fine pitch wire bonding on pad sizes from 60-70 microns

Die Attach

Our ESEC 2008SC WAFER die bonder machines can handle 6”, 8”, and 12” wafers

Encapsulation

The MUEHLBAUER CMT6550 & MUEHLBAUER CMT6560 machines are installed with the latest Micropross MP300C2/C3/MT1/MT2/CL3 encoders. They can be used for testing, initialization, and loading of chip operating systems.

Testing

The CMT 6550 & CMT 6560 is installed with the latest Micropross MP300C2/C3/MT1/MT2/CL3 encoders. They can be used for testing, initialization, and loading of operating system.

Leading Biometric Capabilities

Our proprietary smartcard module IC component production technology enables highly customized biometric module assembly for innovative new products.

Capabilities on Biometric applications:

- Fingerprint Sensors

- Secure Element Module with embedded passive components

- Secure Element Module with LED

- Multiple Chips Module with embedded passive components

Automated Optical QA Inspection

While many chip module manufacturers rely on random visual assembly checks of product samples, we augment that with automated optical inspection (AOI) using our own proprietary technologies.

Our AOI technology incorporates camera and image recognition comparisons to ensure all modules meet quality standards.